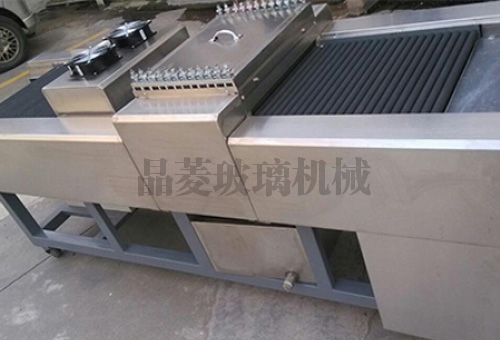

What are the operating rules of the glass cleaner? The operating rules of the glass cleaner should be in accordance with the general operating rules of the casting equipment. In addition, the following points should be paid attention to before operation to ensure smooth operation.

Check the leakage of air and water in the pipeline system. If the pipeline system fails, the maintenance personnel should be notified to repair it in time.

2. Check whether the amount of cleaning liquid is enough. If the cleaning liquid is not enough, add it immediately to ensure that the cleaning work can be carried out effectively.

3. first idle, after operation. Before operation, start the test run first, and then let the glass cleaner idle for about 3 minutes. The purpose is to check whether the transmission system and the belt are very smooth, and then determine whether the operation can be carried out before damage to the glass.

4. remove oil slick operation. Before operation, the oil slick in the machine should be removed first, and the oil slick removal device can start to drain oil. Why choose the machine before operation, because the pump is still in a static state and the interior is relatively quiet at this time, the effect of oil drainage is the best.

The operation rules of glass cleaning machines also include requirements for operators:

1., it is not possible to press the cleaned parts onto the rollers and have a neat discharge on the conveyor belt.

2. the cleaning parts on the conveyor belt should not be excessive. If the quantity is too much, the cleaning effect will be affected.

3. Cleaned parts can no longer be parked on the conveyor belt. All stop buttons should be pressed immediately to stop operation.

4. The cleaning fluid and water should be supplemented in time to ensure that the height of the liquid level does not decrease. If the cleaning effect is not complete, the operator should replace all the cleaning fluid to ensure the completion of the operation.