Advantages and characteristics: professional engraving machine manufacturer curtain wall aluminum veneer engraving machine. The large-scale professional numerical control cutting machine for aluminium sheet is an independently developed numerical control cutting machine for aluminium sheet by Foshan Jingling Glass Machinery Co., Ltd. It aims at the professional NC cutting equipment developed for the growing popularity of decorative materials such as aluminum veneer, fluorocarbon spraying board, aluminum plastic board, special-shaped cutting, grooving, marking and other railway stations, light rail subway, light aircraft, heavy machinery marking, spare parts production.

This industry requires high processing speed, no damage to the surface of aluminium, good accuracy, no grease scale after processing, good smoothness and other special requirements. Compared with other similar devices,

Do not damage the material and use the milling cutter to ensure that the workpiece is not damaged.

Clean natural oil mist cooling, no pollution after processing, easy to post-treatment.

Efficient and convenient, according to the customer receipt of CAD or CorelDRAW drawings can be converted into machine processing code, without lofting and other equipment assistance, directly processing products and workpieces required by customers, computer typesetting saves materials.

The machine works 8 hours a day, up to 500-1000 square feet.

High precision, high workpiece finish, compared with customer drawings, error is less than 0.5MM, workpiece finish is good, smooth and burr-free, no need to grind.

The unique pneumatic positioning pressure plate device has the advantages of accurate feeding, high speed and high efficiency.

This product is widely used by aluminum veneer curtain wall manufacturers in Foshan, Guangzhou, Dongguan, Shenzhen, Zhejiang, Jiangsu, Shanghai, Wuhan, Beijing, Shenyang, Dandong, Tianjin, Zhengzhou, etc. It has won the favor and support of customers and has good practicability.

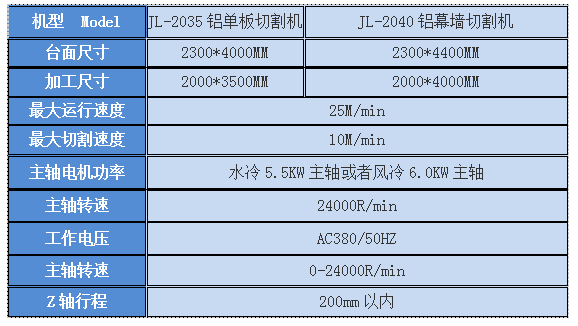

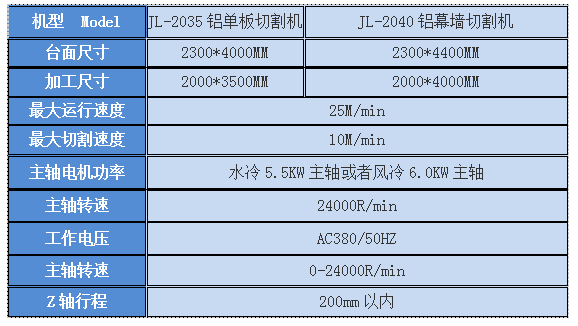

Technical note:

CNC single-board cutting machine is a CNC Mechatronics product. With international standard instructions, it can connect CAD/CAM series software. It can easily complete the three-dimensional processing of computer design. Its precision is higher than 0.025 mm, and its technical level is equal to that of similar CNC equipment in the United States.

The function of automatic tool setting is to measure the origin of material surface with only one touch.

The unique point movement [stepping] numerical control function can precisely adjust the position of the tip of the knife.

Allow machining speed and speed to be adjusted dynamically during processing.

Software control automatically completes multiple surface 3D processing.

Intelligent 3-D computer numerical control function, truly realize the three-axis linkage, can carry out fast and smooth three-dimensional processing, drilling or special-shaped cutting, special-shaped cutting, hollow carving and other processes.

Materials can be extended arbitrarily along the front and rear directions to facilitate processing.

Application: aluminum single plate shaped cutting train, subway station signage production aircraft, heavy machinery parts processing industry, industrial processing, wire cutting, wood furniture manufacturing, toy industry, decoration industry, etc..

Available materials: aluminum plate, aluminum curtain wall plate, fluorocarbon spraying plate, aluminum plate, organic acrylic plate, engineering hard plastic, acrylic, copper and other metal synthesis.

Performance characteristics:The high speed, high efficiency, speed up to 20 meters per minute, 3MM aluminum plate cutting speed can reach 1.5M/min - 4M/min

The power: cutting, cutting and drilling of aluminum disposable knife 3---8MM, cutting edge smooth, no burr, no deformation.

High accuracy: computer control, accurate positioning for small objects.

The good stability: 24 hours a day, can stop at any time low waste processing,

The excellent parts: the German high temperature tempering gear transmission, imported linear guide, the use of excellent stepper system, imported bearings, imported high-power air-cooled spindle motor.

The reasonable design: the gear and rack transmission, advanced speed, high strength, smooth smooth cutting section.

Software compatibility: it can be compatible with Type3/Artcam/castmate/ and other CAD/CAM design and production software.

It has excellent performance: breakpoint, failure recovery, processing time prediction function, the real humanization design.

This high performance CNC cutting equipment is cutting 2MM-4MM tailored for aluminum curtain wall factory, special CNC special-shaped material cutting machine equipment. It can bring great benefits to your company. Note: super large processing equipment can be customized according to user needs.

High accuracy: computer control, accurate positioning for small objects.

Good stability: can work 24 hours a day without interruption, can also be processed at any time to stop, low waste rate.

Excellent components: high temperature tempering hobbing transmission made in Germany, imported linear guide rail, high quality stepping system, imported bearings, high-power imported air-cooled spindle motor.

Reasonable design: advanced rack-and-pinion transmission with high speed, high strength and smooth cutting section.

Software compatibility: it can be compatible with Type3/Artcam/castmate/ and other CAD/CAM design and production software.

Performance worry-free: with breakpoints, power failure recovery, processing time prediction and other functions, a truly humanized design.

This high-performance CNC cutting equipment is a special CNC cutting machine for special cutting and blanking of 2MM-4MM tailored for aluminium curtain wall factory. It can bring great benefits to your company.

Note: super large processing equipment can be customized according to user needs.